The images are all over social media. Doctors and nurses wearing masks for prolonged periods of time during the COVID-19 pandemic, with one of the results being pain and discomfort around the ears. To help ease some of that pain, instructors at Kwantlen Polytechnic University (KPU) have produced 1,000 “ear savers” for healthcare professionals at Vancouver General Hospital.

“The idea with these straps is that the masks are just held around the head,” says Victor Martinez, a product design instructor at KPU’s Wilson School of Design. This relieves pressure on healthcare workers’ ears.

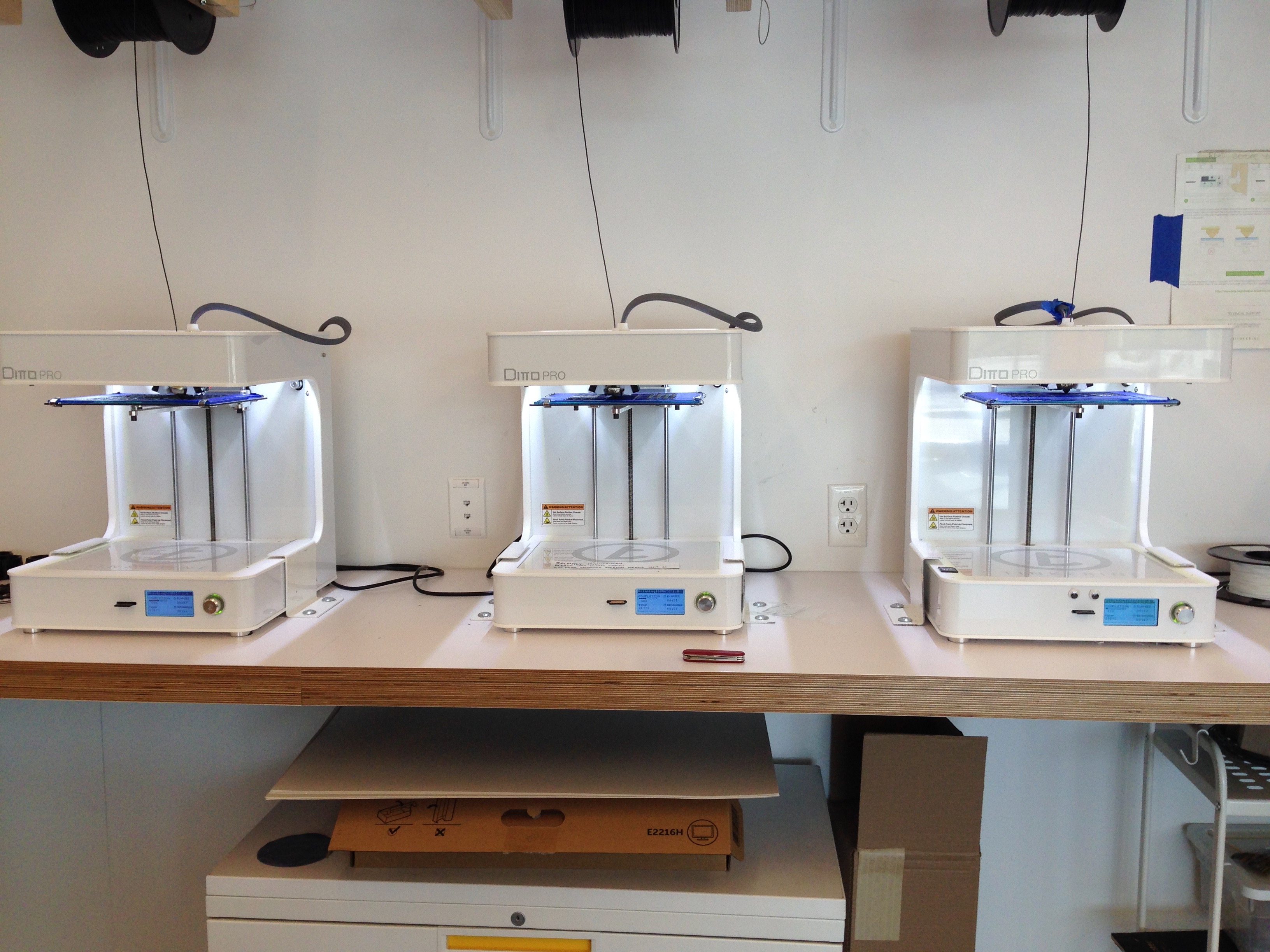

Martinez and a group of KPU faculty and students are using 3D printers to produce the ear savers – adhering to proper physical distancing measures as they work. The printers are running about 15 hours a day.

The ear savers attach the mask straps that would otherwise go around the ears to small notches on the plastic devices, which then wraps around the head easing the discomfort behind the ears.

This small project is part of a wider global commitment to responding to issues and concerns about personal protective equipment (PPE) for workers on the front line of the pandemic.

“Victor has been diligently and tirelessly working on possible PPE solutions since the initial need was first announced,” says Andhra Goundrey, dean of the Wilson School of Design.

While balancing the transition to online teaching and finishing the spring semester remotely, Martinez worked with an existing design to create the straps. Given his background in design and 3D printing, he wanted to do something to help front line workers.

“Although he was amidst working through the shift to online course delivery and finishing off the semester with his students and despite some challenges to further clarify regulations, he did not sway from his intentional pursuit to find ways to contribute to this cause.”

Five instructors in KPU’s Physics department are also involved, including Michael Chernoff, James Hoyland, Takashi Sato, Fergal Callaghan, and Flavio Ruiz-Oliveras.

“The physics instructors thrive on challenges and this is part of the long-term ongoing close teaching and research relationship between faculty from two very different disciplines. It is a great example of the KPU spirit of collaboration and community service,” says Elizabeth Worobec, dean of the School of Science and Horticulture.

Two Product Design students, Birk Zukowsky and Russell Kirstein, and one Interior Design student, Leo Zhuo, are also using their personal 3D printers to help deliver the products.

“It is great. Being able to contribute, even if just a little bit makes a huge difference, it is about feeling useful and that we are truly in this together,” says Martinez.