At Kwantlen we use a number of new or more efficient technologies that reduce our energy consumption and our environmental footprint. The information that follows provides a brief summary regarding some of the technologies that we use to make our energy efficiency program successful.

Photovoltaic (Solar)

Cloverdale Campus has a photovoltaic system that provides electricity to our main electrical system. The collectors are located on the south side of the east wing of the building just below the roof line. There are two collectors installed which are the same size. Each supplies electricity to an inverter which is connected to the buildings electrical system. This system reduces electrical consumption.

Geo-Exchange

Surrey Campus has a geo-exchange system that heats and cools the majority of the Arbutus building (Library) as well as the new addition of the Maple building. The system uses a series of wells that are about 200 feet deep which are located on the east and north sides of the Maple building. These wells supply heat pumps located in each building.

The new Institute of Sustainable Horticulture (ISH) Greenhouse at Langley Campus has a geo-exchange system that can be used for research purposes. It also has a backup high efficiency condensing boiler that can be used if the heat pump is not in service. This combination will allow us to quantify the differences between the two heating technologies.

These systems reduce natural gas consumption for heating and greenhouse gas emissions but our electrical consumption related to heating increases. This type of electric heat uses about 1/3 the energy that traditional electric heat uses.

Condensing Boilers

At Langley and Surrey Campuses we have installed condensing boilers to carry the base heating load during most of the heating season. This reduces natural gas consumption and greenhouse gas emissions.

Natural Ventilation

Surrey Campus uses a natural ventilation system to ventilate the majority of the Arbutus building and the new area of the Maple building. The system uses cabinets called trickle vents to allow fresh air to enter the building which are located on all sides of the building for each level of the building. CO₂ sensors are installed throughout the occupied spaces to control the ventilation to match the demand. Each trickle vent is open during occupied hours and fresh outside air can enter the building evenly to all areas on the outside wall. In winter months the air passes through a heating coil to heat it up as it enters the building. This system reduces electrical consumption and provides a steady supply of heat at a low level, to maximize comfort levels.

Demand Ventilation

Every campus employs demand ventilation in areas with a high variable occupancy. Demand ventilation measures CO2 levels in the air and adjusts the air volumes to these areas to maintain CO2 levels at optimum values based on the number of occupants in the room. One way to explain this is that a classroom with 25 occupants needs more volume of air than a classroom of the same size area with only 5 occupants. Increasing the volume of air to the room increases the amount of energy necessary to heat or cool the air and also the amount of electricity for the supply fan to provide the additional air to the space. This reduces gas and electrical consumption as well as greenhouse gas emissions.

Radiant Floors

Surrey Campus uses radiant floor technology to heat and cool the majority of the Arbutus building as well as the new area of the Maple building. This type of heating and cooling is more energy efficient in how it heats or cools people and it also increases the effectiveness of our geo-exchange system as the geo-exchange system produces cooler heating water than a conventional boiler. To get maximum benefit from this lower temperature water a larger heating surface is often necessary. One way to achieve this is to use the radiant floor area to distribute this heat evenly through the building. A key advantage of this is the floor has a lot of mass which tends to store the heat keeping the room temperatures vary constant. In the summer we use cooler water from the geo-exchange to cool the buildings in the same manner. This system improves the effectiveness of the geo-exchange system allowing it to operate in cooler weather reducing natural gas consumption.

Lighting

We use energy efficient lighting technology in a number of ways:

| * Reduced wattage on 24 hour hallway light fixtures which reduces consumption by 25% |

| * LED exit lights |

| * Fluorescents high bay lighting at Cloverdale in shop areas |

| * Occupancy sensors in classrooms and washrooms where practical |

| * Daylight controls in areas with high levels of natural light to turn off lights on bright days |

| * Automatic systems to turn off non-essential lighting when we are closed |

| * Low-Voltage Lighting control systems connected to the Building Automation System |

Electric Motors

We use high efficiency motors on new projects and have retro-fitted older motors to high efficient where practical. When we have a diversity of loads, we use variable speed drives on larger motors to control motor speed to system capacity requirements for air handing systems and pumps. The ability to slow the speed of the heating water distribution increases our ability to drop the water temperature to ensure we are operating in the condensing temperature range, thus maximizing our boiler system efficiency. Also this reduces electrical consumption.

Results

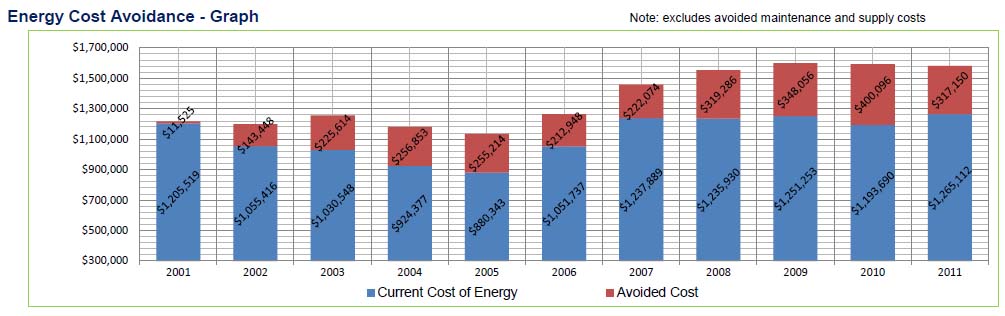

We have been performing energy efficiency retro-fits for over 10 years. The graph below shows our annual energy cost avoidance since the year 2000.

Additional Information

Additional information on the technology we use and the work we have performed to reduce energy consumption and greenhouse gas emissions is in our "Strategic Energy Management Plan"